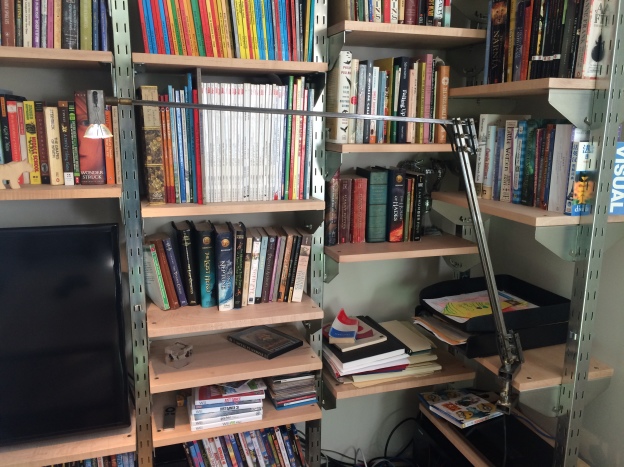

This lamp, initially used as a desk lamp, was built and partially designed by my grandfather. I came up with the overall concept and dimensions but since I didn’t know (and still don’t) how to weld, he did all the manufacturing. He was also really good at finding and repurposing parts designed for different applications. The interesting thing about this lamp are the parallelograms at the base and elbow. These allow to have 6 points of friction to maintain the angle and hold the lamp in place without having springs or counter-weights.

My grand father picked all the parts, including the brass screws with the wingnuts and some hard white plastic washers. He spent quite some time trying to find the right amount of friction. I have to tighten or loosen the nuts from time to time to keep the lamp “tuned”, easy to move around but never sagging. He also came up with the idea to hide the wiring in the metal profiles and took special care to bend the metal around the openings for the wire.

For the base, he designed an oversized C clamp. The detail that puts a smile on my face is a grey plastic cap of an old photo film roll used as padding. This would be hard to find these days.

The head is connected to the arm using a brass balljoint which allows for it to tilt. I have no idea where he found it but it’s perfect. To hold the bulb in place, he used a spring with hooks. I believe these were originally intended to hold and hang decorative plates.

He finally glued two blocks of oak to make a large brick that he carved to hide the power supply.